Views: 18 Author: Site Editor Publish Time: 2023-05-22 Origin: Site

Abstract: With the development of technology, more electronic devices are widely used in various industries, such as mobile phones, computers, tablets, game consoles, robots, and so on. Due to the use of high-density integrated circuits, heat is generated more intensively inside these devices, leading to a sharp increase in device temperature. When the temperature of the equipment exceeds a certain range, it will affect the service life and safety of the equipment. In electronic products, thermal runaway may lead to material thermal aging, as well as component damage, which can also affect the product's service life and even endanger personal safety. A well-known example is the Samsung NOTE 7 phone battery explosion in 2016. During the product development stage, designers did not detect this hidden danger, and safety incidents occurred frequently after the product was circulated to the market. Samsung has had to implement a global recall, resulting in direct economic losses of billions of dollars. The brand losses caused by this incident are even more incalculable!

Keywords: radiator; Heat dissipation performance; stability

1.1 Thermal design is based on the thermal characteristics of electronic components and the principles of heat transfer, and various structural measures are taken to control the working temperature of electronic equipment, making it within the allowable temperature range.

1.2 The transfer methods of heat include heat conduction (the phenomenon of direct energy exchange between objects at different temperatures), convection (the flow caused by different densities), and radiation (photon transfer, without the need for a medium). It can appear separately or in two or three forms simultaneously.

1.3 The purpose of thermal design is to use heat transfer characteristics to apply appropriate cooling technology and structural design to the heat consuming components and the entire machine or system of electronic equipment, in order to control their temperature rise and ensure the normal and reliable operation of electronic equipment or system.

1.4 Thermal design process: thermal design (requirement analysis) → thermal evaluation → thermal analysis → thermal simulation → thermal testing

2.1 Passive Heatsink: commonly used in low-power devices.

2.2 Active Fansink: commonly used in high power devices.

2.3 Liquid cooling system: commonly used in high/ultra high power devices

Passive heat dissipation should be given priority among all heat sinks, as it is not only cost-effective but also highly reliable. Only when passive heat dissipation cannot meet the heat dissipation power consumption, other cooling schemes should be considered. The following figure shows the simple selection principle of heat sinks.

Main radiator data and financial indicators of some leading enterprises in the radiator sector (extracted from a certain public information)

The market heat of the radiator industry continues to rise, and the continuous innovation in technology, safety, and variety is the fundamental reason for its leapfrog development in application scenarios. The surge in user demand in the radiator industry has greatly broadened the breadth and breadth of its applications. One manifestation is the further integration of raw materials and suppliers in the radiator industry chain, which is more conducive to the upgrading and restructuring of the industry source end and the optimization of industrial processes; The second manifestation is the rapid iterative update of radiator technology, quality, and variety, which is more conducive to the continuous upgrading and quality improvement of products and further meets the different new needs of users. All of the above are conducive to the further development and progress of the radiator industry. At the same time, the integration of multiple parties has led to a stronger development of product applications in the radiator industry.

The industry channel of radiator industry is mainly composed of upstream products and services, namely raw material and service manufacturers, intermediate service integration, namely product and service integrators, product service design, namely design planners, industry agents, namely industry products and service agents, industry dealers and consumers, namely industry products and service dealers and consumers. Formed a complete radiator industry structure in the upstream, midstream, and downstream.

1. Raw material and service manufacturers, representing upstream products and services, mainly responsible for including the original manufacturers of products and services, including various raw material manufacturers.

2. Product and service integrators, representing intermediate service integration, are mainly responsible for the reprocessing services of upstream services and are the embodiment of upstream service integration.

3. Design planners, representing product and service design, mainly provide professional design and standard planning for the whole business transformation.

4. Industry product and service agency, representing industry agency, mainly responsible for upstream industry services and product agency services.

The distributors and consumers of products and services in the industry represent the distributors and consumers of the industry. This section mainly consists of various distributors and users of consumer products and services in the industry.

Based on the commercialization process and investment status of radiator technology in China in recent years, it is analyzed that the commercialization level of radiator technology will further improve in 2023. With the continuous improvement of commercialization level, investment in the field of radiator technology in China will gradually transition from the current focus on venture capital to investment mergers and acquisitions between enterprises, especially for some emerging enterprises that hope to quickly enter the radiator field, Entering through mergers and acquisitions has the advantage of rapid layout. Meanwhile, with the gradual maturity and commercialization of radiator technology, the competitive position of industry leading enterprises will gradually be consolidated. For some entrepreneurial enterprises, the threshold for seeking financing with venture capital institutions will also increase.

The era of large-scale project investment has passed, and precise investment in the industrial chain is being implemented. The new economy and new investment will become a new trend for future development. The core ideas for attracting investment in the new economy mainly include platform investment, new business formats investment, and technology investment.

Step 1: Build an industrial cluster around radiator unicorn enterprises;

Step 2: Build intelligent service carriers, such as specialized maker spaces, intelligent park services, and intelligent infrastructure;

Step 3: Establish an innovative service system for the radiator industry, provide financial services such as funds, activity services, and business model services, build an open and complete industrial ecosystem, and drive the explosive development of radiators with the rapid growth of enterprises.

1. Slow service update speed

The update speed of radiator services is slow and cannot meet the needs of users in a timely manner.

2. The service experience needs to be improved

The radiator service experience is poor and unable to gain more favor from users.

3. Information asymmetry

Unable to provide professional information acquisition and sharing services for users, and unable to meet the informationization needs of heat sinks.

4. Insufficient consultation and management

The current consulting perspective in the radiator industry cannot focus on user needs and pain points.

Ningde Era Kirin Battery Cooling Solution

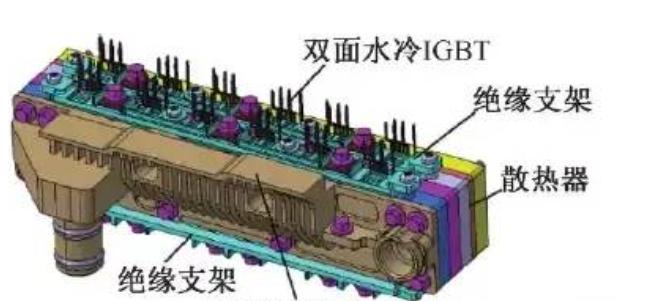

Double sided water-cooled IGBT and radiator module

Ionic wind heat dissipation