Views: 54 Author: Site Editor Publish Time: 2021-11-17 Origin: Site

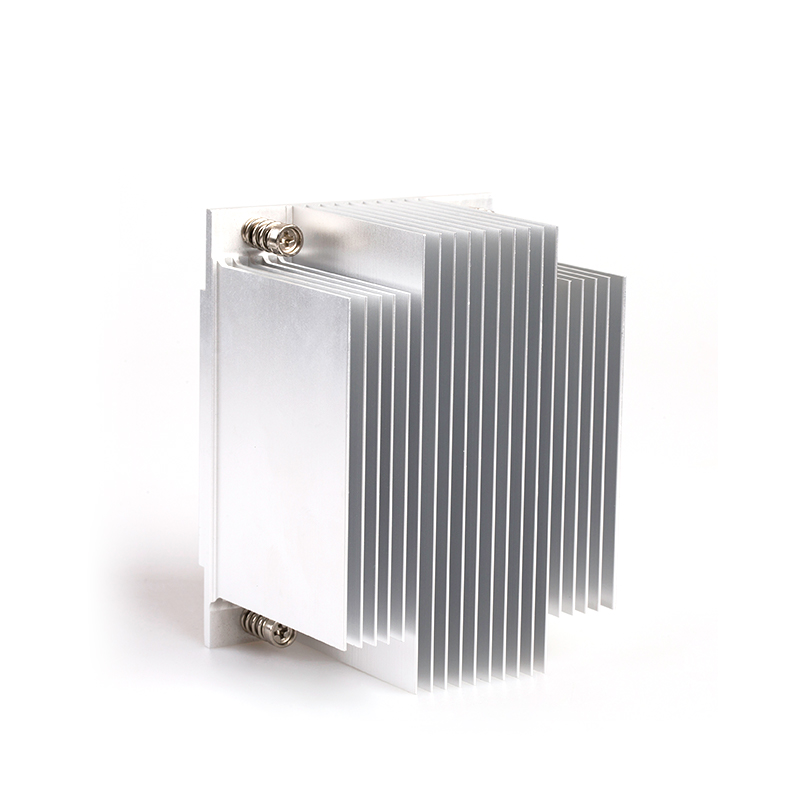

The computers, air conditioners, and heating equipment we use are equipped with custom heat sinks, which can prevent the equipment from overheating and damage the equipment. Which material is better for custom heat sinks? The performance of the heat sink made of each material is also Different.

Custom heat sinks are arranged according to its thermal conductivity from low to high: steel, aluminum, copper, silver, but if silver is used to make heat sinks, it is obviously expensive and not suitable, so we generally use copper to make heat sinks Although aluminum is cheaper, its thermal conductivity is too poor.

The advantages of aluminum alloy are low price and light weight, but the thermal conductivity is much worse than copper. Some radiators take their own strengths and embed a piece of copper on the base of the aluminum alloy radiator. For ordinary users, the use of aluminum heat sinks is sufficient to meet the heat dissipation requirements.

At present, the most used materials for heat sinks are copper and aluminum alloy. Both have advantages and disadvantages. Copper has good thermal conductivity, but the price is more expensive than aluminum alloy, the processing difficulty is higher, the weight is too large, and the heat capacity is too high. It is small and easy to oxidize. But pure aluminum is too soft to be used directly. The aluminum alloy used can provide sufficient hardness.

Summary: Through the above introduction, I believe that everyone also understands the advantages and disadvantages of various materials. The custom heat sink we use is generally made of copper and aluminum alloy.